Manufacturer of Textile Inks For Silk Screen Printing - Pure Natural Acid Printing Paste LH-317H – Yiman Lanhua

Manufacturer of Textile Inks For Silk Screen Printing - Pure Natural Acid Printing Paste LH-317H – Yiman Lanhua Detail:

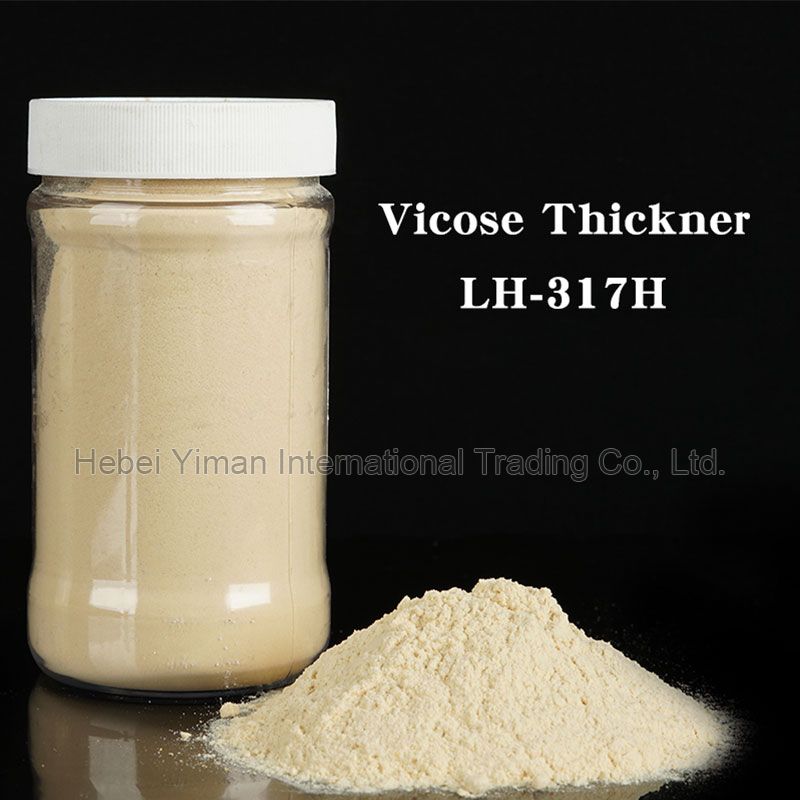

Vicose Thickener LH-317H

-A kind of guar gum.

- LH-317H is suitable for the acid printing of natural silk and nylon, it has excellent fluidity, can be used in the rotary or flat screen printing. Meanwhile, LH-317H can also be used in the disperse printing, reactive printing, burnt discharge printing and discharge printing. Suggest stirring fully before use to achieve better printing performance. Pay attention that it will agglomerate when mixed with borate or tannic acid.

Key Features and Typical Benefits:

- Good water solubility, can puff and thicken after stirring in cold water.

- Good fluid and penetration performance.

- Clear outline, high color yield, bright-colored, easy to be washed off and good handleing.

- As a pure natural thickener and environmental friendly product, it does no harm to environment.

- Excellent stability to chemical reagents, such as acid(citric acid, tartaric acid) and some reducing agent(stannous chloride).

Properties:

| Property | Value |

| Physical Form | Solid |

| Appearance | Beige powder |

| pH value(10% aqueous solution) | 6.5-7.5 |

| Water Content (%) | ≤10.0 |

| Ionic Character | Nonionic |

Application:

1. Recipe of acid dyes printing

LH-317H 10%

Water or other chemicals 90% Total 100%’

Note: Dissolve LH-317H into cold water slowly and keep fast stirring for at least 40mins to prevent agglomeration occurring 。 Keep the paste standing for a whole night to make maximum puffing. Hot water(around 70℃) can accelerate the puffing。After fully puffing, take 50-80% paste to make color paste. Add organic acid such as tartaric acid or citric acid to adjust pH to around 5.0(no need to adjust pH when used in reactive printing). According to the experience, use 200 mesh sieve to filter the paste before using.

2. Process flow: Paste Preparation—Rotary or flat screen printing-Drying-Steaming or baking (102-105℃, pressure 0.09-0.1MPa, 30-50 min)-Washing

Note: Detailed process should be adjusted according to preliminary tries.

Operating and safety instructions:

1. Suggest weighing and diluting separately when preparing the paste, then add respectively and stir fully.

2. Strongly recommend using soft water in dilution, if soft water is not available, the stability needs to be tested before making the paste.

3. Do not keep for long time after dilution.

4. To ensure the safety, you should review our Material Safety Data Sheets before using this product under special conditions. For Material Safety Data Sheets, contact Lanhua Chemical Group. Before handling any other products mentioned in the text, you should obtain available product safety information and take necessary steps to ensure safety of use.

Package & Storage:

Bag net 25 kg, Pay attention to moisture, can be stored for 6 months under room temperature and hermetic condition without exposure to sunlight. To ensure that the product quality is maintained, please check the period of validity of the product, and should be used up before the validity. The container should be tightly sealed when not in use. It should be stored without prolonged exposure to extreme heat and cold conditions.

ATTENTION

The above recommendations are based on comprehensive studies conducted in the practical finishing. They are, however, without liability regarding property rights of third parties and foreign laws. The user should test whether the product and the Application: are suited for his very special purposes.

We are, above all, not liable for fields and methods of Application: which have not been put down by us in writing.

Advice for marking regulations and protective measures can be taken from the respective safety data sheet.

Product detail pictures:

Related Product Guide:

Adhering to your principle of "quality, assistance, performance and growth", we have now gained trusts and praises from domestic and international customer for Manufacturer of Textile Inks For Silk Screen Printing - Pure Natural Acid Printing Paste LH-317H – Yiman Lanhua , The product will supply to all over the world, such as: Swaziland, Georgia, Iraq, We also have good cooperation relationships with many good manufacturers so that we can provide almost all of auto parts and after-sales service with high quality standard,lower price level and warmly service to meet demands of customers from different fields and different area.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.