Hot Sale for Textile Ink For Screen Printing - Urea Substitute/Urea replacer LH-391H – Yiman Lanhua

Hot Sale for Textile Ink For Screen Printing - Urea Substitute/Urea replacer LH-391H – Yiman Lanhua Detail:

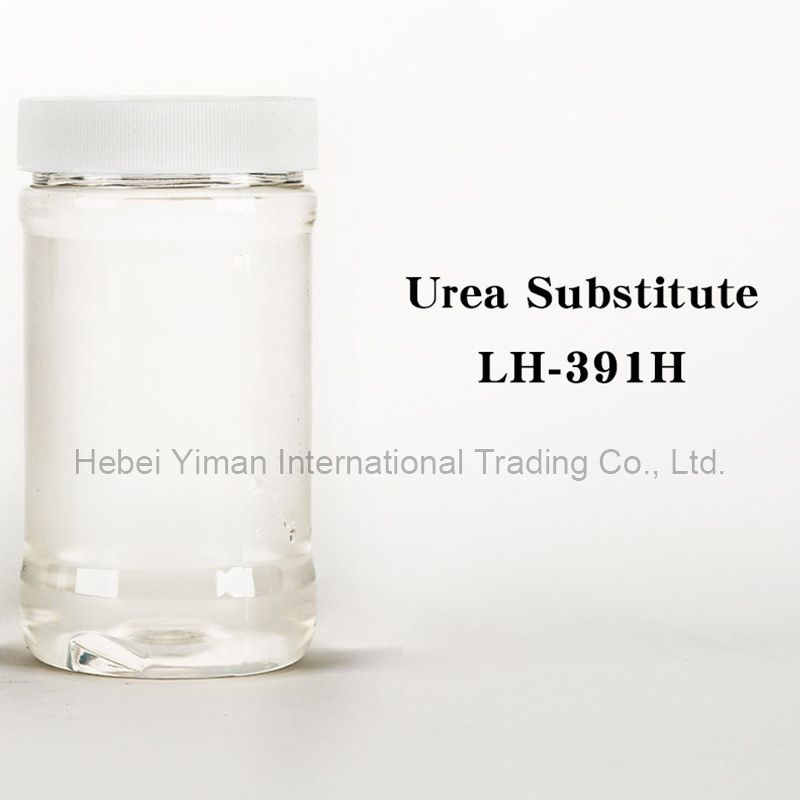

Urea Substitute Introduction:

-Urea substitute can be used to replace urea in reactive printing.

-LH-391H urea substitute is a kind of special molecular compound. It is very suitable for reactive printing for cotton or viscose fabric.

Key Features and Typical Benefits:

◆ Has the functions of hydroscopic, dissolving and assists the swelling of fibers.

◆ Can replace urea to be used in reactive printing for cotton or viscose fabric without impacting the color achieved.

◆ Can obviously decrease the ammonia contents in the waste water.

LH-391H Urea Substitute Properties:

| Property | Value |

| Physical Form | Liquid |

| Appearance | Colorless transparent liquid |

| pH(1% aqueous solution) | 6.5-8.5 |

| Sugar degree(%) | 27.0-30.0 |

| Ionic characteristic | Weak cationic |

Urea Substitute Application:

1. Recipe:

| Water | X g |

| Urea | 0g-10g |

| Urea substitute LH-391H | 10g-0g |

| Resist salt S | 1g |

| Sodium hexametaphosphate | 0.5 – 1g |

| Sodium carbonate | 1-3g |

| Thickening agent | Yg |

| Reactive dyestuff | Z g |

| Total | 100g |

LH-391H can replace urea completely, or be mixed with urea by 1:1, 1:2 or other ratio, the specific dosage should be adjusted by the requirement or processing condition of customers.

2. Process flow:

Paste preparation—Rotary or flat screen printing-Drying(100-110℃, 1.5-2min)-Steaming (101-105℃, 8-10 min)→Washing

Precautions

Operating and safety instructions:

1. Suggest weighing and dilution of the agents respectively when preparing the paste, then add one by one and stir fully.

2. Strongly recommend using soft water in dilution, if soft water is not available, the stability needs to be tested before making the solution.

3. After dilution, it should not be stored for a long time.

4. To ensure the safety, you should review our Material Safety Data Sheets before using this product under special conditions. MSDS is available from Lanhua. Before handling any other products mentioned in the text, you should obtain available product safety information and take necessary steps to ensure safety of use.

Package & Storage:

Plastic drum net 120 kg, can be stored for 6 months under room temperature and hermetic condition without exposure to sunlight. To ensure that the product quality is maintained, please check the period of validity of the product, and should be used up before the validity. The container should be tightly sealed when not in use. It should be stored without prolonged exposure to extreme heat and cold conditions, which may cause product separation. If the product is separated, stir the contents. If the product is frozen, thaw it at warm condition and stir after thawed.

ATTENTION

The above recommendations are based on comprehensive studies conducted in the practical finishing. They are, however, without liability regarding property rights of third parties and foreign laws. The user should test whether the product and the application are suited for his very special purposes.

We are, above all, not liable for fields and methods of application which have not been put down by us in writing.

Advice for marking regulations and protective measures can be taken from the respective safety data sheet.

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" is definitely the persistent conception of our corporation to the long-term to establish alongside one another with customers for mutual reciprocity and mutual profit for Hot Sale for Textile Ink For Screen Printing - Urea Substitute/Urea replacer LH-391H – Yiman Lanhua , The product will supply to all over the world, such as: Sacramento, Latvia, Pakistan, Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We are looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.